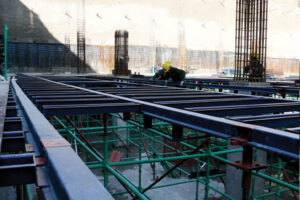

This system is used for wide uniform flat concrete slabs in various ordinary or high rise structures. The speed of forming operations is much higher as compared with traditional systems due to simpler fittings and components. Moreover, the finished concrete surfaces exhibit a higher quality and higher uniformity because of the plywood toppings used in this type of forming

Advantages of SK Formwork System:

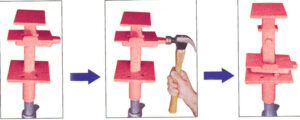

• The specially designed drophead system (locker-release mechanism) makes it possible for the lower scaffolding system to act independently of the upper formwork system (steel beams), offering a great advantage as compared with the traditional systems. Thus, as the systems act independently to each other, it is possible to remove the main and secondary metal beams used as forming elements (which need not be under load during concrete hardening) can be removed before the required strength for the concrete has been obtained, while the lower scaffolding system as well as the supports Remains under load. This possibility not only considerably accelerates construction due to elimination

of unnecessary waiting times during forming operations, but also reduces forming costs and, consequently, other related costs.

• The modular system components utilized to minimize the reuse costs when reusing them in other projects

• The high assembling/dismounting speed of SK formwork system due to the facilities provided by carefully designed fittings and lightweight components, as well as non-use of any cranes whatsoever

• The time required for SK formworks is half that for modular formworks used for flat slabs

• High quality of exposed concrete surfaces due to use of plywood in SK formworks

• Easy construction of flat concrete slabs in various thicknesses and heights due to high flexibility and dimensional diversity of SK system components

• Possibility of re-using the cup-lock scaffolding system for face scaffolding upon completion of formwork and concrete roof operation

Ceiling Mantling System, BFS-Flex contains a limited number of light and portable parts in which it is useful for the operation of various plans and flat slab thicknesses in addition to its ease of use and the quick and simple installation and uninstallation.

Slab Mantling System, BFS-Flex containing parts:

-Surface plywood

-Initial and secondary (H20) Tim bers

-Main carrier’s telescopic props

-Subsidiary (middle) carrier’s telescopic props

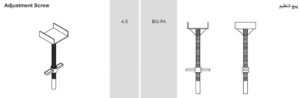

-Fork head for the main telescopic props

-U-shaped head for the subsidiary telescopic props

Uni-Tripod Stand

-Installation and on installation fork of (H20) Tim bers

Slab Mantling System, BFS –Flex, installation stages:

1. Installation of the main telescopic props, the Fork Head and the 3 pole stand

2. Arraying the height of the main ceiling’s telescopic props

3. Installation of the initial or main (H20) Tim bers

4. Installation of the secondary or subsidiary of H20 Tim bers

5. Installation of the covering plywood

6. Installation of the subsidiary telescopic props

The Use of H20 timbers as main and cross beams ensure that large spans and possible.

The Universal H20 timber slab formwork system for any ground plan and all floor heights.